Building your own ice rink is an exciting idea, especially if you want a space that brings people together for skating, training, or community events. While the project can feel complex at first, understanding the cost drivers and planning each stage properly makes the process far more manageable.

This guide breaks down ice rink construction costs, explains the pricing differences between indoor, outdoor, and synthetic rinks, outlines the major factors that influence your budget, and explores available financing options.

You’ll also get a clearer sense of what to expect from the construction process itself. With the right information, you can approach your rink project with confidence.

Factors Affecting Ice Rink Construction Costs

Building an ice rink comes with several variables that can push your budget up or down. Location, size, construction methods, and material choices all influence how much you’ll spend. The type of rink you’re looking to build, whether it’s for recreational use, school programs, or professional training, affects requirements for ice quality, support systems, and overall design.

Understanding these factors early helps you estimate both the upfront investment and the ongoing maintenance costs with far more accuracy. Below we’ve outlined the key factors that shape overall construction pricing.

Size and Layout

The size and layout of an ice rink significantly influence construction costs because larger surfaces require more materials, labor, and time. Costs also rise when projects include additional spectator areas, wider dasher boards, or multi-use layouts. Standard dimensions for various types of ice rinks are as follows:

- Hockey rink: 200 feet by 85–100 feet (60 x 26–30 m)

- Figure skating rink: 200 feet by 100 feet (60 x 30 m)

- Olympic rink: 200 feet by 98–100 feet (60 x 30 m)

NHL and Olympic-size rinks typically require higher-capacity refrigeration systems and thicker ice floors, which further increases overall expenses. Enlarging an existing ice rink can also impact the project cost, with expansions often ranging from $100,000 to over $1,000,000 depending on the new dimensions and structural requirements.

Additional costs may arise with larger layouts, including transport, construction, rink accessories, and specialized equipment needed to support the increased scale.

Rink Type: Indoor vs Outdoor

Indoor and outdoor ice rinks provide distinct skating experiences and have unique construction needs and costs. Indoor ice rinks typically have higher construction costs due to the need for a building structure, insulation, and climate control systems.

In contrast, outdoor ice rinks have lower initial costs but may require more maintenance due to weather exposure, especially when it comes to maintaining center ice. They also offer less control over ice quality throughout the season, which can influence long-term upkeep planning.

Indoor Rinks

Indoor ice rinks require a building structure, climate control, and insulation to maintain a consistent ice surface. The ice rink cost, estimated for construction, ranges from $100,000 to $950,000 for a rink with real ice and $14,000 to $395,000 for a synthetic ice rink.

Size is a major contributor to the overall cost, so if you can get away with a smaller sheet of ice, you can save a tremendous amount of money. The expense of building an indoor ice rink depends on different aspects like the rink’s size, location, and specific project requirements.

Additional costs, such as labor, equipment, and extra amenities or features, must also be taken into consideration. As a general rule of thumb, assuming between $200-250 per sq ft is a good start point for light industrial new building construction.

Outdoor Rinks

Outdoor ice rinks require a simpler construction process, with costs ranging from $25,000 to $150,000. However, outdoor rinks may require more maintenance due to exposure to weather conditions, such as temperature fluctuations and precipitation.

Even though the construction costs are lower, outdoor ice rinks still need to consider recurring expenses like water and electricity for maintaining the ice. The cost of constructing an outdoor hockey rink can vary greatly, with basic community rinks ranging from $50,000 to $500,000.

Ongoing Maintenance

Regular maintenance is essential for keeping the ice smooth, safe, and consistent. For refrigerated rinks, upkeep involves several recurring tasks, including:

Regular maintenance is essential for keeping the ice smooth, safe, and consistent. For refrigerated rinks, upkeep involves several recurring tasks, including:

- Maintaining the ice layer at the desired thinness

- Deep-cleaning the ice surface

- Meeting specific temperature and humidity conditions for proper ice-making

- Checking and verifying ice thickness

- Cleaning the rink surface before new ice is applied

How often these tasks are needed depends on the rink’s size, the level of daily activity, and the type of skating or sport being played. Most rinks benefit from scheduled maintenance every four to seven days, although larger or heavily used facilities may need more frequent attention to maintain optimal ice quality.

Materials and Construction Methods

The materials and construction approach you choose have a significant impact on total ice rink costs. Factors such as slab design, insulation layers, piping density, and the use of reinforced concrete directly influence pricing.

Higher-quality materials may increase upfront expenses but often deliver greater durability, better ice quality, and lower long-term operating costs. Since 2020, the average cost of construction materials has risen by 19 percent due to inflation, supply chain disruptions, and increased demand.

Indoor rink projects often require additional components that elevate the budget, including steel framing, roofing, insulation, vapor barriers, and architectural finishes. Clear-span structures, which allow for open space without internal support columns, are typically more expensive.

Rink features like dasher boards and glass also vary widely in cost. Standard boards and basic acrylic offer affordability, while high-impact glass, flexible board systems, and professional-grade safety features significantly increase the price. Keeping track of material trends and cost fluctuations during planning helps ensure your project stays aligned with both performance goals and budget expectations.

Location and Site Conditions

Location has a substantial impact on both construction and long-term operating costs. Soil quality, the level of site preparation required, and local permitting processes can all influence your upfront budget. Energy prices and climate conditions also affect operational expenses, especially when it comes to maintaining stable ice quality throughout the season.

Remote areas may face higher transportation and labor costs, which can add to the overall project total. These considerations often shape design choices, equipment selection, and the level of infrastructure required to support consistent rink performance over time.

Ancillary Equipment

Offering rental skates and equipment is essential for attracting customers and generating revenue. The rink cost, including the cost of rental skates at an ice rink, can vary depending on the location and type of skates. To reduce the cost of procuring rental skates and equipment, consider acquiring used items, collaborating with local skating clubs or suppliers for cost-effective pricing options, or outsourcing to an external vendor.

Expect to pay around $60-100 for a bulk order of user-friendly buckle up skates, whereas high end hockey and figure skates can cost between $400-800 per pair. To keep a well maintained and smooth surface on refrigerated ice, make sure to look into Zambonis as well.

Providing well-maintained rental skates and equipment ensures a positive experience for your customers and helps to maintain a reputable image for your ice rink. So include the annual expenditure for routine maintenance and repair of rental skates and equipment.

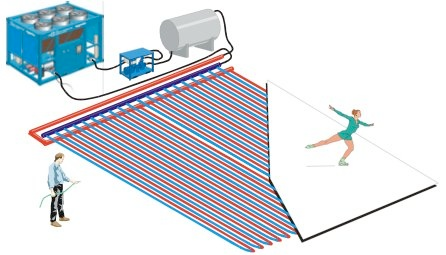

Refrigeration Systems

Refrigeration is one of the biggest cost drivers in ice rink construction. Your choice of refrigerants, chiller capacity, and overall system efficiency directly affects both upfront investment and long-term operating costs. Most rinks use 1 of 4 primary refrigeration setups:

- Ammonia/CO₂

- Ammonia/glycol

- CO₂

- Freon

These systems can operate as either direct or indirect refrigeration. In a direct system, the refrigerant flows through piping under the ice slab itself, creating highly efficient cooling but increasing complexity, safety requirements, and installation cost.

In an indirect system, the refrigerant cools a secondary fluid (often glycol) that circulates beneath the ice. This approach is slightly less efficient but offers easier maintenance, safer handling, and lower risk, which can reduce certain cost pressures.

Installing an ice rink refrigeration system typically requires several days, often up to four, depending on the setup. Costs vary dramatically based on the size of the rink and system complexity, ranging from several hundred thousand dollars to several million for high-capacity or professional-grade configurations.

HVAC and Dehumidification

Ice facilities rely on specialized HVAC systems to control temperature, manage humidity, and keep the ice surface stable throughout changing conditions. Without proper dehumidification, warm, moist air can lead to fogging, soft ice, condensation on the structure, and even water dripping onto the surface.

These systems must be sized to handle frequent air exchanges, spectator heat load, and the moisture created by resurfacing equipment. While dehumidifiers and high-capacity HVAC units can be expensive, they play a critical role in preventing structural damage, reducing energy waste, and ensuring the ice remains consistent and safe for users.

Amenities and Extras

Amenities and facilities, such as locker rooms, seating areas, and concession stands, can enhance the customer experience and increase profitability. Installing seating areas in an ice rink can also vary in cost.

Setting up a concession stand at an ice rink may also contribute to the overall cost. You can opt for a pre-made booth or construct a new medium-sized concession stand. Constructing your booth rink will be more expensive than getting an already constructed one. Providing a variety of amenities and facilities can help to attract more customers and improve their overall satisfaction with your ice rink.

Refrigerated vs Synthetic Ice Rinks

During the planning phase of your ice rink project, comparing refrigerated and synthetic ice rinks is important to decide the most suitable option for your specific needs. Refrigerated ice rinks utilize real ice created by freezing water and require constant maintenance and resurfacing. On the other hand, synthetic ice rinks implement a form of plastic ice and require less maintenance.

The cost of constructing a synthetic ice rink is typically lower than that of a refrigerated ice rink. Synthetic ice rinks also offer environmental benefits, as they do not require electricity or water for maintenance and are composed of sustainable materials.

Besides lower acquisition and maintenance costs, synthetic ice provides several other advantages. Synthetic ice rinks can be used year-round, providing a consistent skating experience regardless of climate or weather conditions.

They also reduce water consumption and energy costs compared to traditional ice rinks, making them a more environmentally friendly option.

Synthetic ice rinks provide a safe and enjoyable experience for skaters of all levels and require minimal maintenance to perform optimally. With their versatility and cost savings, synthetic ice rinks are an attractive choice for many ice skating enthusiasts and facility owners.

Synthetic Ice: Is It Better?

Synthetic ice, a substitute for traditional ice rinks, offers benefits like lower acquisition and maintenance costs and environmental advantages. Composed of a solid polymer material, synthetic ice rinks can be installed using interlocking panels to create a durable and long-lasting surface.

Procurement Costs

The estimated acquisition costs for synthetic ice can range significantly, beginning at a few hundred dollars and escalating to several thousand dollars for larger rinks. The average cost of synthetic ice depends a lot on the supplier, differentiating in quality.

By offering a more affordable option compared to traditional ice rinks, synthetic ice allows for the creation of ice rinks in locations and climates where maintaining a refrigerated ice rink would be cost-prohibitive or environmentally unsustainable. As a general rule of thumb, synthetic ice rinks cost around $16-28 per sq ft, depending on the quality, connection system, thickness, and supplier.

Maintenance Costs

Maintenance expenses for synthetic ice are considerably less than traditional ice rinks, as there’s no need for refrigeration systems or ice resurfacing gear. The only maintenance needed is regular cleaning and in most cases the application of lubricants or other maintenance liquids. Here are some tips for the necessary cleaning and maintenance:

- Clean the surface regularly with soap and water or the manufacturer’s maintenance solution.

- Sweep the surface before mopping to remove any loose debris.

- Deep-clean the surface at least once a week to remove any built-up dirt or grime.

- No special chemicals are needed for cleaning.

- With proper care, a synthetic ice rink can last for many years.

Financing Options for Ice Rink Construction

Financing the construction of an ice rink can be a substantial challenge, but there are several alternatives that can help fund your project. Some viable financing options for ice rink construction include:

- Government grants

- Private investors

- Bank loans

- Crowdfunding

These options provide flexibility for funding the project. Government grants can help cover costs associated with constructing or rehabilitating public and recreational facilities, as well as grants for female hockey programs and community-based ice rinks.

Private investors can offer equity financing or loans, while bank loans can provide traditional financing options, such as Small Business Administration (SBA) loans and commercial construction loans.

Crowdfunding can also help collect small amounts of money from a large number of people, allowing individuals or organizations to contribute to the project and receive rewards or incentives in return.

Frequently Asked Questions

Building or maintaining an ice rink comes with several practical considerations, and certain questions tend to come up more often than others.

The following FAQs outline key points across cost, construction, maintenance, and timing to give a clearer sense of what’s involved. This part serves as a quick reference for the fundamentals before you explore the details further.

How Much Does It Cost to Build an Ice Rink?

The cost of building an ice rink varies widely depending on factors such as size, whether the rink is indoor or outdoor, the type of refrigeration system, and the quality of construction materials.

Small outdoor community rinks may start around tens of thousands of dollars, while full-scale indoor facilities with advanced refrigeration, insulation, and building structures can run into the millions.

Labor, site preparation, utilities, and features like boards, glass, and seating also influence the total budget. Because so many variables are involved, early planning and a clear scope of work are essential for an accurate cost estimate.

Do Ice Rinks Make a Profit?

Ice rinks businesses can be profitable, but success depends heavily on financial structure, operating efficiency, and year-round utilization. Many rinks struggle because revenues fluctuate seasonally, while expenses such as energy, staffing, and equipment maintenance remain constant.

Ice rinks businesses can be profitable, but success depends heavily on financial structure, operating efficiency, and year-round utilization. Many rinks struggle because revenues fluctuate seasonally, while expenses such as energy, staffing, and equipment maintenance remain constant.

Profitability becomes more realistic when a facility has low or no debt service, meaning fewer loan obligations cutting into revenue. Rinks with diversified income streams, such as public skating, lessons, leagues, rentals, events, and off-ice programming, tend to perform better.

Can You Make Your Own Ice Rink?

Yes, you can build a simple home ice rink with basic materials such as plywood walls or hay bales to create a perimeter. The purpose of the border is to contain the water and provide a level frame as the ice forms.

A liner is typically added to hold the water, and once the temperatures drop low enough, the rink freezes into a usable surface. While this DIY approach is cost-effective and straightforward, it requires a flat area and consistent cold weather to maintain good ice quality.

How to Build a Hockey Rink?

Building a backyard hockey rink starts with staking out the desired area and assembling a sturdy box frame around the perimeter. If the ground isn’t level, an additional layer or higher boards may be needed to ensure the water fills evenly.

Once the frame is secure, a rink liner is installed, followed by filling the area with water and allowing it to freeze. After the ice sets, you can maintain the surface with regular flooding or light resurfacing. This creates a reliable at-home space for practice and recreational skating.

How Thick Should a Home Ice Rink Be?

A home ice rink should have an ice thickness of at least 5 cm, or about 2 inches, to safely support the weight of skaters. Thinner ice is more prone to cracking or soft spots, especially during periods of temperature fluctuation.

Building up the ice gradually, through multiple thin layers rather than one deep fill, helps ensure a solid, durable surface. Thicker ice may be necessary in areas with frequent use or slightly warmer winter temperatures.

When Should I Build an Ice Rink?

The ideal time to set up a home ice rink is during the early winter months. Installing the frame in November or December gives you enough time to prepare the area, while adding the liner in December or January typically aligns with the coldest temperatures needed for freezing.

Your local climate is the determining factor, so even if you miss those months, you can still build a rink as long as the conditions are consistently cold. Freezing temperatures for several consecutive days are key for developing stable, skateable ice.

Key Takeaways

Building an ice rink involves a mix of technical choices and budget considerations, including everything from site conditions and rink size to materials, refrigeration, and ongoing maintenance. Each decision influences both the upfront investment and the long-term operating demands of the rink.

Understanding how these factors interact makes it easier to plan realistically, whether the goal is a refrigerated facility or a simpler synthetic setup. With a clear approach and an informed budget, an ice rink can become a reliable, well-functioning space that’s used and enjoyed season after season.

If you’d like to understand more about the technology, installation options, or maintenance needs, we encourage you to view our FAQ. For project support, tailored guidance, or any other questions you might have, please reach out to our team. We’re happy to help!